Press hardened steel a similar technology that heats ultra high strength steel until it is formable runs at about 930 c says mohammed gharbi director of technology and process development at the schuler group.

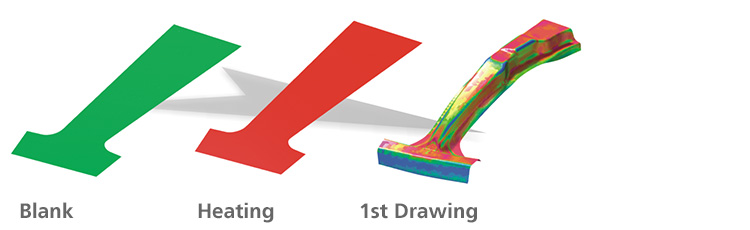

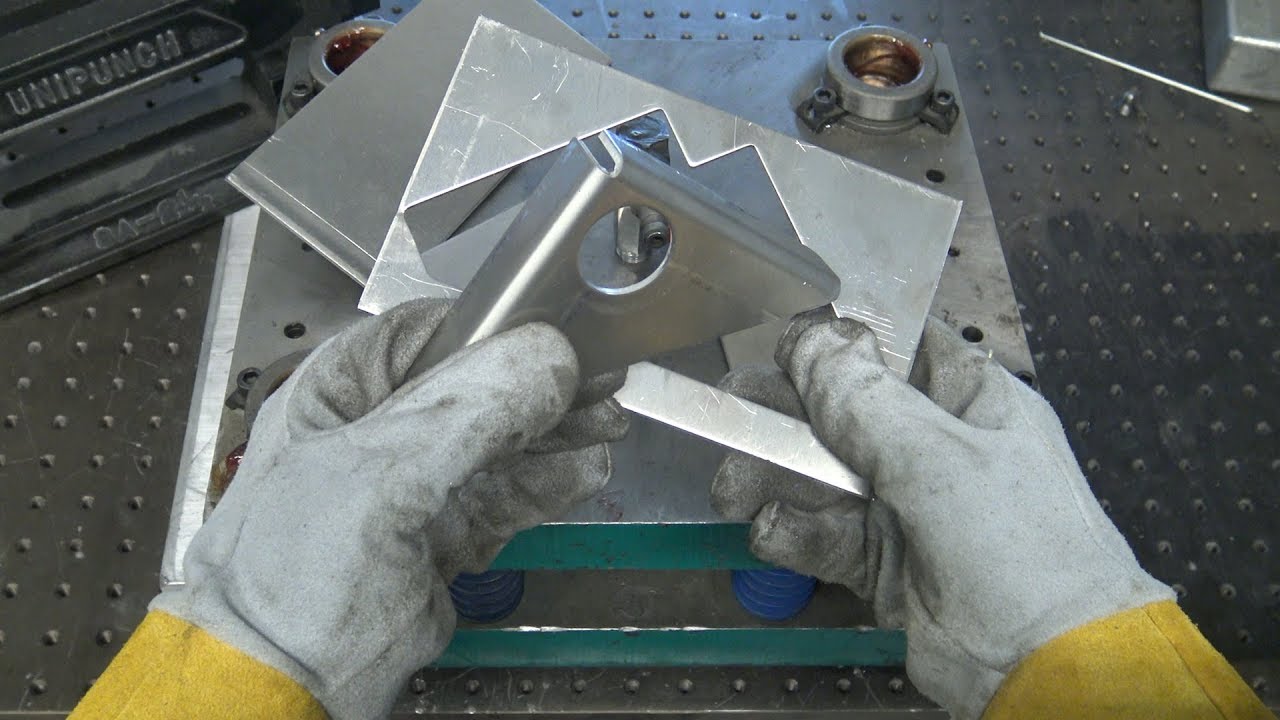

Hot forming aluminum sheet.

Either warm forming less than 482 degrees f or hot forming about 887 degrees f the alloy s solvus temperature can be used.

Temperatures range from 600 c to 980 c depending on customer specifications and the material used.

In this metal forming process a sheet of metal is passed through perforating scissors where it is cut and stretched into a pattern.

This forming process is commonly used for manufacturing fences catwalks platforms grating etc.

This tech tip is related to their sportster project but can be used on anything you might be working with that requires something built out of aluminum sheet.

Introduction aluminum sheet metal alloys are prime candidates for use in the automotive industry because of their good strength and stiffness to weight ratios.

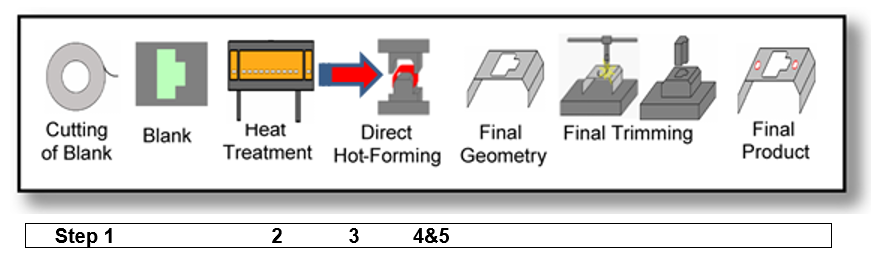

With this method parts are formed in their soft state at elevated temperatures and then quenched in the tool.

The hot sheet metal is brought into contact with the hot die whilst the hot punch descends into the die and shapes the.

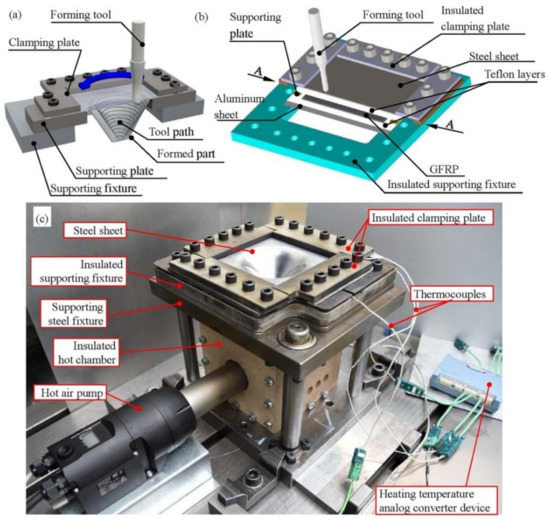

A hot blow forming method for the aluminum alloy sheet carries out a hot blow forming to an aluminum alloy sheet using a first metal mold being a female mold for forming having a protruding surface portion on an inside surface thereof and a second metal mold for gas introduction.

The drawback to their widespread use is their room temperature formability.

Usually a diamond shaped mesh is preferred as it has a structural advantage over other shapes.

Heat treatment in furnace.

Parts produced by hot forming are characterized by high strength complex shapes and reduced springback effects.

After hot forming an artificial aging heat treatment is required to achieve a t6 temper which is lost during the process.

Autoform s software enables you to simulate thermal effects in sheet metal forming.

In this paper the hot forming quenching integrated process of 6a02 aluminum alloy sheet at different forming dies temperatures ranging from 50 degrees c to 350 degrees c was investigated.

Hot draw forming the hot forming process is similar to traditional cold forming but involves heating the tool and component.

Immediately prior to the hot blow forming a temperature t 1 of the aluminum alloy sheet and a temperature t 2.

Aluminum alloys possess only moderate formability at room temperature.

When the autoform thermo plug in is used in connection with autoform software you can consider general thermal effects in cold warm and hot.

Hot forming of these alloys greatly improves their formability and this.

Hot forming hot forming is a temperature and time dependent process.

A few tier 1 suppliers already practice et forming of aluminum alloys.

The hot forming process consists of the following steps.